Automotive cooling systems are pressurized because regular coolant has a low boiling point, which isn’t great for keeping an engine cool. Pressurization helps by making the coolant better at its job. When it’s pressurized, like around 15 pounds per square inch (PSI), the coolant doesn’t boil as easily.

However, this means it can do a good job of keeping the engine from getting too hot without disappearing into steam. To put it simply, pressurization stops the coolant from boiling away, which could cause the engine to overheat or even get seriously damaged, like a blown head gasket or a warped cylinder head.

Let’s explore more details.

Cooling System Overview

A cooling system is a critical component in various machines and vehicles, designed to regulate and maintain an optimal operating temperature. This is particularly important for the proper functioning and longevity of engines, electronics, and other heat-generating systems. Here’s a simple overview of a cooling system:

Purpose: The primary purpose of a cooling system is to prevent overheating. It achieves this by dissipating excess heat generated during the operation of an engine or electronic components.

Components: A typical cooling system consists of several key components:

- Radiator: This is a heat exchanger that helps cool the circulating fluid (usually coolant or antifreeze).

- Coolant: A special liquid mixture that absorbs heat from the engine and carries it to the radiator.

- Water Pump: A pump that circulates the coolant throughout the system.

- Thermostat: A valve that regulates the flow of coolant to maintain the desired temperature.

- Fans: Electric fans that help increase airflow through the radiator when needed.

- Hoses and Pipes: These carry the coolant between different parts of the system.

Operation: It works by circulating coolant through the engine and other heat-producing components. As the coolant flows, it absorbs heat and carries it to the radiator. There, the heat is dissipated into the surrounding air, which helps regulate the system’s temperature.

Maintenance: Proper maintenance is essential to ensure effectiveness. This includes checking coolant levels, inspecting hoses for leaks, and ensuring the radiator is clean and free of debris. Regular flushing and replacing of the coolant are also important.

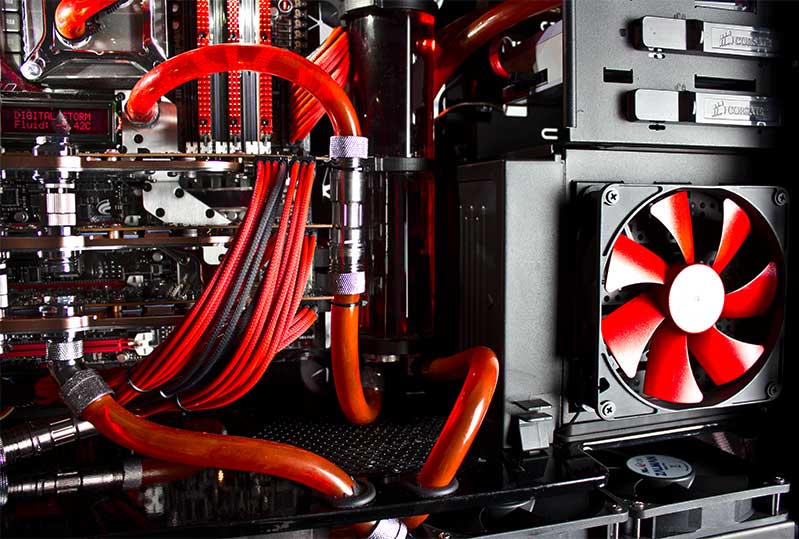

Types of Cooling Systems: There are various types of cooling systems, including air cooling and liquid cooling. Liquid cooling is more common in vehicles and high-performance electronics, as it is more efficient in dissipating heat.

Signs of Problems: When a cooling system malfunctions, it can lead to overheating and potentially damage the engine or components. Signs of cooling system issues include high engine temperatures, coolant leaks, unusual engine noises, or warning lights on the dashboard.

How To Pressure Test Your Cooling System

To make sure your car’s cooling system is working well and doesn’t have any leaks, you can do a simple test. You’ll need a special kit for this. Here’s how it works:

- Connect the kit to where the radiator cap usually goes. This makes a sealed space for the test.

- Use the hand pump to build pressure in the system. You want to match the pressure written on the radiator cap. Most cars have a pressure between 13 and 16 PSI. This helps make the test realistic.

- Let your car sit with this pressure for about 20-30 minutes. This gives it time to see if it can keep the pressure.

- Look carefully at the whole cooling system to check for any leaks. You don’t want any parts that might cause problems.

- Keep an eye on the pressure gauge on the kit while you wait. If the pressure goes down, it could mean there’s a leak. That’s a sign you need to find and fix it.

- You should also check the radiator cap itself. Most testing kits come with an adapter for this. Here’s how to do it:

a. Put the adapter on the kit and then attach the radiator cap to the adapter.

b. Use the hand pump to reach the pressure level shown on the cap.

- Pay close attention to the pressure in the cap to see if it changes. If there are leaks, you’ll usually notice them quickly. But if you’re not sure, keep the pressure for a few more minutes. If it doesn’t drop, your cap is good. If it does drop, it’s time to get a new cap.

Need for Pressurization

The need for pressurization in various systems and applications is driven by several important factors and purposes. Pressurization serves critical functions in different contexts, ensuring safety, efficiency, and reliability. Here’s an overview of the need for pressurization:

Boiling Point Elevation: One primary reason for pressurizing a system is to raise the boiling point of the fluid within it. When a liquid is pressurized, its boiling point increases. This is particularly important in applications where high temperatures are involved, such as in steam boilers, where pressurization prevents the water from boiling at lower temperatures.

Enhanced Heat Transfer: It can significantly improve the heat transfer properties of a system. This is particularly valuable in cooling systems and heat exchangers, where maintaining higher pressure can lead to better heat dissipation and more efficient temperature regulation.

Preventing Fluid Boil-Off: In systems where fluids are involved, maintaining pressure prevents the rapid boil-off of the liquid. For example, in cryogenic applications where extremely cold temperatures are required, pressurization helps keep gases in a liquid state to avoid wastage or inefficiencies.

Leakage Prevention: Pressurizing a system can help seal potential leak points. It forces components together and reduces the risk of leaks in pipelines, joints, and seals, ensuring the system’s integrity and minimizing the loss of valuable fluids.

System Efficiency: Many industrial processes rely on pressurization to improve overall system efficiency. This can include the compression of air or gases, which is essential in various manufacturing and energy generation processes.

Controlled Environments: In controlled environments, such as cleanrooms or laboratories, pressurization helps maintain specific air pressure levels to prevent contamination from external pollutants. Positive or negative pressure can be applied to ensure a controlled atmosphere.

Safety: In some cases, pressurization is used for safety purposes. For instance, in nuclear reactors and chemical processing plants, maintaining pressure is critical to contain hazardous materials and prevent the release of potentially dangerous substances in the event of an accident. When you need to read coolant pressure accurately while keeping corrosive additives safely isolated, a chemical seal pressure gauge fits the bill perfectly.

Regulation of Fluid Flow: Pressurization is essential for regulating fluid flow in pipelines and hydraulic systems. It helps maintain the desired flow rate and ensures that fluids are delivered consistently and efficiently to their intended destinations.

System Integrity: lastly, it can help maintain the structural integrity of certain components, preventing deformation or collapse under external loads. This is particularly important in applications like pressurized vessels and aircraft cabins.

Minimizing Fluid Loss

Minimizing fluid loss is super important in many places like factories, businesses, and the environment. It brings lots of benefits that help us manage liquids and gases better.

Fluids, whether they’re liquids or gases, are valuable. When we stop them from leaking or spilling, we save these important resources, reduce waste, and save money. This also helps protect nature because it’s eco-friendly.

Further, being efficient is another big deal. Some systems, like hydraulics, need just the right amount of fluid to work well. When we prevent fluid loss, these systems run smoothly and do their job right.

Safety is a big deal too, especially when we deal with dangerous liquids or gases. Stopping fluid leaks makes the workplace safer, prevents accidents, and helps equipment last longer.

When we lose them, it can mess up how systems and processes work. Imagine a hydraulic system losing fluid – it can’t do its job properly. By stopping fluid loss, we make sure everything works smoothly and reliably.

In systems with pressure, like in machines or pipes, we need to keep the pressure level right. Also, it helps maintain that pressure and keeps things running well. And in places where the stuff we handle must be super clean, like in medical equipment or semiconductor factories, we have to stop doing it to keep things pure and safe.

Ways to Minimize Fluid Loss:

- Check your equipment and pipes regularly to catch any potential leaks or damage. Fix them right away.

- Make sure the seals and gaskets are okay. If they’re not, replace them to stop leaks.

- Teach your team how to handle liquids and machines properly. This reduces the chance of mistakes that could cause leaks.

- Install systems that can find leaks and tell you about them quickly so you can fix them.

- Store and use liquids in a way that prevents spills and leaks.

- Use materials for your equipment and pipes that don’t easily wear out or corrode. This reduces the risk of leaks.

- Stick to environmental rules and do things the right way to reduce the impact of leaks on nature.

Pressure Control

Pressure control is essential for maintaining the right pressure levels in various systems. It ensures that these systems, including hydraulic and pneumatic systems, as well as industrial processes, work correctly. Safety is a primary concern, especially when dealing with high pressure, and effective pressure control helps prevent equipment failure and dangerous accidents.

In addition, proper pressure control also extends the lifespan of equipment and components, reducing replacement costs and downtime. In manufacturing, it is critical for product quality, ensuring consistency and preventing defects. Additionally, it contributes to energy efficiency, reducing operational costs and conserving resources.

In simple terms, it keeps things running smoothly and safely, making systems more reliable and cost-effective.

Ways to Achieve Pressure Control:

Pressure Regulators: These are like automatic pressure controllers. They manage pressure by adjusting how much fluid or gas flows. You find them in things like gas pipelines, water systems, and heating and cooling systems.

Valves and Dampers: Think of these like volume controls. They change how fast things flow to control pressure. They’re used in factories and heating and cooling systems too.

Pressure Relief Devices: These are safety heroes. When the pressure gets too high, they open up and let some out to prevent things from breaking. You’ll see them in boilers, big tanks, and pipelines.

Pressure Sensors: These are like pressure detectives. They keep an eye on pressure and tell the control system. This helps maintain the right pressure levels.

Automation and Control Systems: Imagine a robot that manages pressure for you. That’s what these systems do. They can keep pressure just right and adjust when needed.

Regular Check-ups: Pressure control devices need regular check-ups. It’s like going to the doctor for a check-up. They get inspected, calibrated, and get new parts if needed.

Safety Rules: Every team needs safety rules. These rules help in pressure emergencies. They might include shutting things down in an emergency and using safety relief devices.

Learn and Train: Make sure your team knows how to handle pressure control systems and what to do in emergencies. This keeps everyone safe and things running smoothly.

FAQ’s

How is the cooling system Pressurized?

The cooling system becomes pressurized as the coolant heats up and expands, raising the system’s pressure. This is beneficial because higher pressure increases the coolant’s boiling point, preventing it from boiling at 100°C, much like a pressure cooker cooks at high temperatures without boiling food.

Why is a radiator still pressurized after cooling?

Radiators remain pressurized because the radiator cap acts as a pressure-release valve, allowing liquid or vapor to escape when the preset pressure (usually 15–16 psi) is reached. This extra pressure prevents the glycol-water mixture from boiling at a higher temperature, similar to a home pressure cooker.

What happens if the cooling system is not pressurized?

If your cooling system lacks pressure due to a faulty radiator cap or its absence, the boiling point of the water/coolant drops, causing the engine to overheat. An overheated engine often shuts down.

Does the cooling system increase pressure?

Yes, as the coolant heats up, it expands, leading to increased pressure within the system. The advantage of this increased pressure is that it raises the coolant’s boiling point, preventing it from boiling at lower temperatures. For example, pure water boils at 212°F at atmospheric pressure.

How pressurized is a radiator?

The pressure rating of a radiator cap varies based on its original application, typically ranging from 13 psi up to 18 psi.

Final Words

To sum it up, pressurizing a liquid-cooled system, like in cars, is super important. It fixes the problem of coolant that can easily boil and not cool the engine well. When we add pressure, the coolant can handle more heat.

Additionally, at about 15 PSI, the boiling point goes up by around 45 degrees Fahrenheit compared to the non-pressurized coolant. This means the coolant stays liquid and keeps the engine cool instead of turning into steam.

In simple terms, pressurization prevents the coolant from boiling away, which could lead to problems like engine overheating, damage, or a blown head gasket. So, pressurization is like a superhero for liquid-cooled systems, keeping the engine safe and working well.