Possible causes for a high-pitched squeal from a car when moving that stops when braking include worn brake pads, which may need replacement, or a loose or worn belt in the engine compartment, which may need tightening or replacement.

Have you ever hopped into your trusty four-wheeled companion, only to be greeted by an unexpected high-pitched serenade as you hit the road?

It’s like your car is trying to join a choir, right? Now, imagine this curious symphony subsiding when you tap on the brakes.

What’s up with that musical interlude? Join me on a little journey as we explore the mystery behind the high-pitched squeal that seems to have turned your car into a temporary songbird.

Buckle up, and let’s unravel this melodic automotive enigma together!

Understanding the High-Pitched Squeal

Detailed description of the sound:

Characteristics of the sound:

Frequency: The high-pitched squeal is characterized by a sharp and shrill tone.

Intensity: It is often loud and can be piercing to the ears.

Duration: The sound may occur intermittently or persistently, depending on the source of the issue.

Possible sources of the sound:

Mechanical components: These could be emanating from moving parts, such as belts, pulleys, or bearings in machinery.

Electrical systems: Faulty electronic components, transformers, or power supplies may also produce high-pitched squeals.

Fluid-related issues: In some cases, issues with fluid circulation, such as in hydraulic systems, can lead to squealing sounds.

Variations in the sound:

The pitch may change based on the speed or load on the affected component.

The sound may be accompanied by other noises, such as grinding, clicking, or buzzing.

Potential consequences of ignoring the issue:

Mechanical damage:

Ignoring a high-pitched squeal from mechanical components can lead to increased friction, overheating, and wear.

Continued use without addressing the issue may fail belts, pulleys, or bearings, causing more extensive damage.

Electrical malfunctions:

If the high-pitched squeal is related to electrical components, ignoring it may lead to electrical failures.

In extreme cases, this could result in equipment malfunction, damage to connected devices, or even electrical fires.

Safety risks:

Squealing sounds in machinery may indicate a potential safety hazard. Ignoring the issue may lead to unexpected equipment failures, posing risks to personnel working in the vicinity.

Reduced efficiency:

Unaddressed high-pitched squeals often indicate inefficiencies in the affected systems. This might lead to lower performance and higher energy usage.

Costly repairs:

Neglecting the early signs of a problem can lead to more extensive damage over time. Delaying necessary repairs may result in higher repair costs and longer downtime.

In summary, understanding and promptly addressing the high-pitched squeal is crucial to prevent further damage, ensure safety, and maintain the efficiency of the affected systems.

Regular maintenance and timely investigation of unusual sounds are essential to prevent costly consequences.

Common Causes

Worn Brake Pads

Explanation of brake pad function:

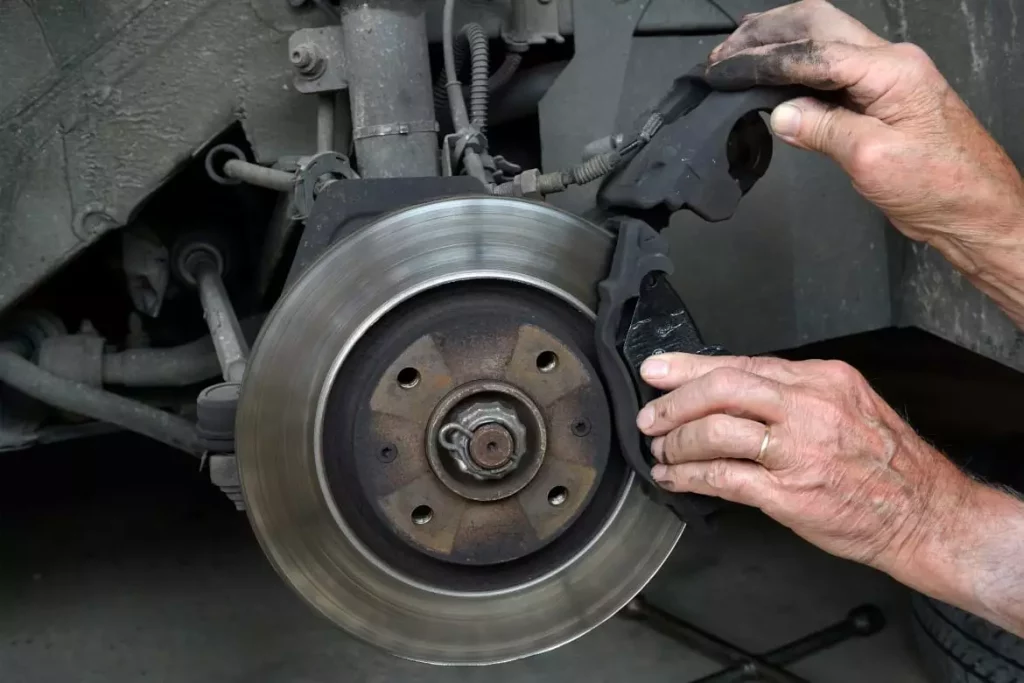

Brake pads are essential components in a vehicle’s braking system. They are typically made of friction material (such as composite or ceramic compounds) and are mounted on a metal backing plate.

Pressing the brake pedal applies hydraulic pressure to the brake caliper, causing it to press the brake pads against the brake rotor (disc).

This friction generates the necessary force to slow down or stop the vehicle.

Signs of worn brake pads:

Squealing or screeching sounds: A high-pitched squeal during braking is a common indicator of worn brake pads.

Reduced braking performance: If the vehicle takes longer to come to a stop or if there’s a noticeable decrease in braking effectiveness, it could be a sign of worn brake pads.

Visible wear: Inspecting the brake pads through the wheel spokes can reveal their thickness. If the pads appear excessively thin, they may need replacement.

Importance of regular brake maintenance:

Timely replacement of worn brake pads prevents damage to other braking system components, such as rotors, which can be more expensive to replace.

Loose or Worn Belts

Signs of loose or worn belts:

Squealing or chirping noises: A high-pitched squeal or chirping sound, especially during acceleration or when turning the steering wheel, may indicate a loose or worn belt.

Visible wear or damage: Inspecting the belts for cracks, fraying, or missing sections can reveal their condition.

Diminished performance of accessories: If the power steering feels less responsive, the battery isn’t charging properly, or the air conditioning is less effective, it could be due to issues with engine belts.

The role of belts in the car’s operation:

Engine belts are responsible for transferring power from the engine to various components, ensuring their proper operation.

A malfunctioning or broken belt can lead to the failure of critical systems, including the charging system, power steering, and air conditioning, affecting the vehicle’s overall performance.

Regular inspection and maintenance of engine belts are essential to prevent unexpected failures and ensure the smooth operation of vital engine components. Replacing belts at recommended intervals can help avoid costly repairs and breakdowns.

DIY Check: Identifying the Issue

Step-by-step guide to safely check for worn brake pads:

Park the vehicle:

Ensure the vehicle is on a level surface and engage the parking brake.

Locate the brake pads:

Identify the brake caliper and locate the brake pads. They are usually visible through the wheel spokes.

Listen for sounds:

Start the vehicle and gently apply the brakes. Listen for any squealing or screeching noises, especially during braking. Such sounds can indicate worn brake pads.

Check both sides:

Repeat the inspection for all four wheels, as brake pads may wear unevenly.

How to inspect belts for wear or looseness:

Open the hood:

Ensure the engine is off and the vehicle is parked securely. Lift the hood to get to the engine compartment.

Locate the belts:

Identify the serpentine belt or other belts in the engine compartment. They are usually visible on the front of the engine.

Visual inspection:

Check the belts for signs of wear, like cracks, fraying, or any missing sections. If you see any visible damage, the belt may need to be replaced.

Check for tension:

Press down on the belt with moderate pressure. A properly tensioned belt should have some give but should not feel overly loose. If it feels too loose or too tight, it may need adjustment.

Listen for noises:

Turn on the engine and listen for squealing or chirping sounds. These noises may indicate a loose or worn belt, especially during acceleration or steering wheel turns.

Tips for a basic assessment before seeking professional help:

Fluid leaks:

Check for any puddles or spots under the vehicle. Fluid leaks like oil or brake fluid may indicate a potential issue.

Unusual odors:

Pay attention to any unusual smells, such as burning rubber or overheating. These could be signs of mechanical problems.

Dashboard indicators:

Pay attention to any warning lights on the dashboard. Modern vehicles have sophisticated onboard diagnostics; illuminated warning lights may provide clues about potential issues.

Unusual vibrations or noises:

Be attentive to any abnormal vibrations or noises while driving. These can be indicative of issues with various components, such as the suspension, exhaust system, or drivetrain.

Record symptoms:

Before seeking professional help, make a note of any specific symptoms or patterns you’ve observed. This information can be valuable for a mechanic when diagnosing the problem.

Preventive Maintenance Tips

Regular inspection schedule for brake components:

Visual inspections:

Perform a visual check of your brake components every six months or at least twice a year.

Inspect the brake rotors for scoring or grooves.

Listen for sounds:

Pay attention to any unusual sounds during braking, such as squealing, grinding, or clicking. Address these issues promptly.

Check brake fluid levels:

Make sure the brake fluid is at the recommended level. Low brake fluid can impact brake performance.

Monitor brake pedal feel:

If the brake pedal feels spongy or requires more effort than usual, it may be a sign of air in the brake lines or other issues. Have it inspected?

Brake system flush:

Think about getting a brake system flush every two years or, as advised by your vehicle’s manufacturer, to keep the brake fluid performing at its best.

Belt maintenance and replacement guidelines:

Visual inspections:

Inspect the engine belts regularly, preferably every month, for

any cracks, fraying, or any visible deterioration.

Tension checks:

Check the tension of the belts periodically. Belts that are too loose can slip, while those that are too tight may cause premature wear on components.

Listen for noises:

During vehicle operation, pay attention to any unusual sounds, such as squealing or chirping. These may indicate issues with the belts.

Replace according to manufacturer recommendations:

Follow the manufacturer’s guidelines for belt replacement, which typically ranges from 60,000 to 100,000 miles, depending on the type of belt.

Timing belt replacement:

If your vehicle has a timing belt, follow the replacement interval recommended by the manufacturer, typically ranging from 60,000 to 100,000 miles or as specified in the owner’s manual.

Importance of addressing issues promptly:

Safety:

Promptly addressing issues with brakes and belts is critical for vehicle safety. Malfunctioning brakes or broken belts can lead to accidents and injuries.

Preventing further damage:

Spotting and fixing problems early on prevents minor issues from turning into more significant and expensive repairs.

Keeping top performance:

Routine maintenance guarantees your vehicle runs at its peak, offering the best fuel efficiency, handling, and overall performance.

Prolonging the vehicle’s life:

Taking proactive measures in maintenance helps stretch the lifespan of different components, minimizing the chances of premature wear and breakdowns.

Avoiding roadside emergencies:

Addressing issues reduces the risk of unexpected breakdowns, preventing inconveniences and potential towing expenses.

In summary, establishing and following a regular maintenance schedule for brake components and belts is crucial for ensuring your vehicle’s safety reliability, and longevity.

FAQs

Are worn brake pads the only reason for a high-pitched squeal while driving?

While worn brake pads are a common cause, other potential reasons include issues with wheel bearings, belts, or even certain components in the suspension.

Brake pads generally need replacement every 25,000 to 70,000 miles, but following the manufacturer’s recommendations is essential.

Are there any DIY solutions to silence the squealing temporarily?

Applying brake lubricant on the back of the brake pads can sometimes reduce squealing, but it’s crucial to address the root cause by replacing worn pads.

Could the high-pitched squeal indicate a more severe problem with the braking system?

Yes, it could. Ignoring the noise might lead to more significant issues, such as damage to the brake rotors or other components.

Should I be concerned if the noise only occurs in specific weather conditions?

Yes, weather conditions can affect brake performance. Moisture or rust on the brake rotors may contribute to squealing, but investigating and addressing is still important.

Can a high-pitched squeal while driving be related to the transmission or engine issues?

It’s unlikely. Such noises are typically associated with braking, wheel, or suspension components rather than the transmission or engine.

Should I seek professional help even if the squealing noise seems to have stopped on its own?

Yes, it’s recommended. A professional should inspect the underlying cause of the noise to ensure the continued safe operation of your vehicle.

Conclusion

Remember to monitor your brakes and belts regularly. Check for any strange sounds, look at the thickness of brake pads, and inspect belts for wear. If you notice any issues, get them fixed right away.

Taking care of these simple tasks ensures your vehicle stays safe, performs well, and avoids unexpected problems. So, don’t forget to give your car a little attention – it goes a long way!