Damascus steel is not inherently stronger than regular steel. Damascus steel is not inherently stronger than regular steel.

The strength of a steel alloy depends on its composition, heat treatment, and other factors rather than whether it’s called “Damascus steel” or “regular steel.”

Damascus steel has unique patterns due to a forging method that involves layering and welding various steel types.

This process can produce blades with unique visual appeal, but the strength of the resulting steel primarily depends on the specific types of steel used and the blacksmith’s skill in the forging and heat treatment process.

Strength in steel is typically measured in terms of tensile strength, yield strength, and hardness.

The strength of Damascus steel can vary widely based on the materials used and the craftsmanship, so it’s not accurate to make a blanket statement about its strength compared to “regular steel.”

What is Damascus Steel?

Damascus steel, also known as Damascene or Wootz steel, is a type of steel with a long and storied history characterized by its distinctive patterns and exceptional quality.

Here’s a concise explanation of its history and characteristics, along with the traditional forging process:

History and Characteristics:

Historical Origins: Damascus Steel has its origins in the Middle East, particularly in regions like India and Syria. It gained prominence during the Middle Ages and is known for its legendary sharpness, toughness, and distinctive visual patterns.

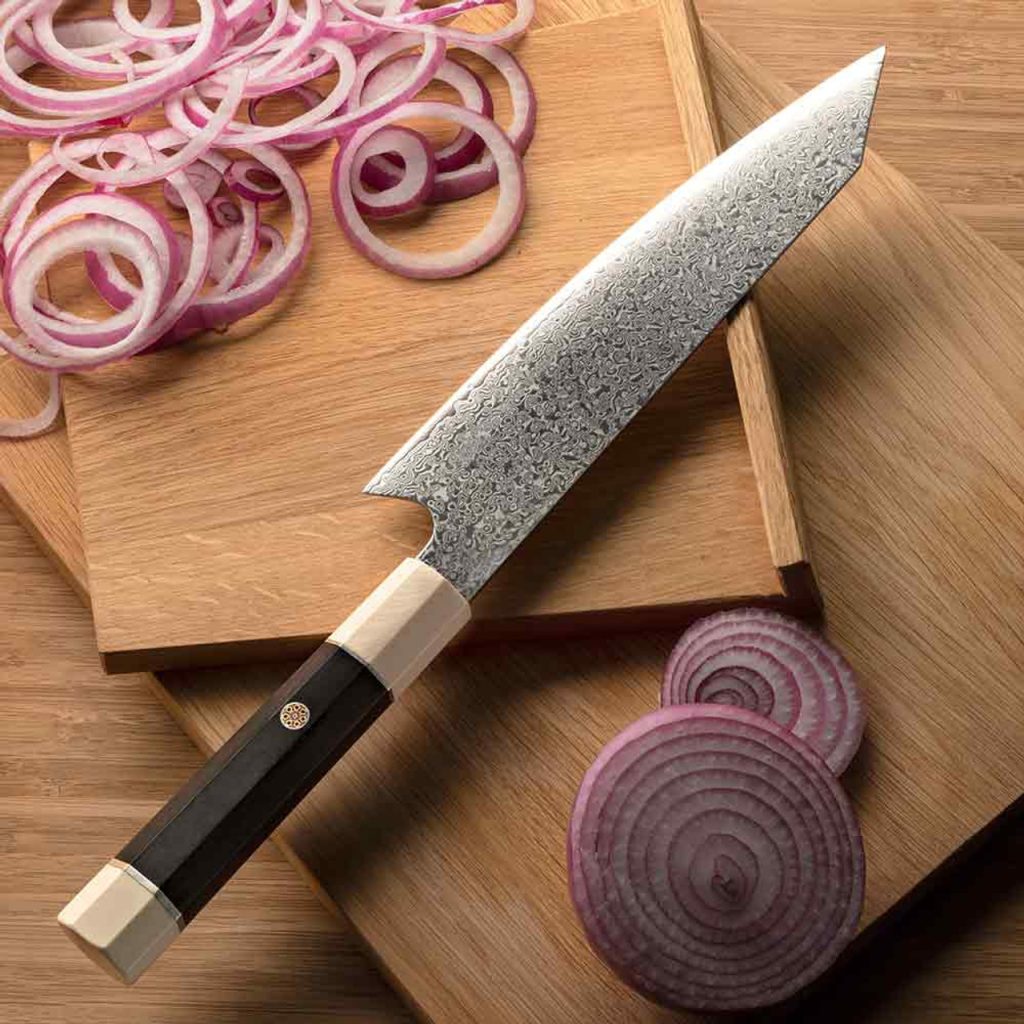

Distinctive Patterns: One of the most recognizable features of Damascus steel is its unique pattern, characterized by wavy or mottled designs on the surface.

These patterns are created by the alternating layers of different types of steel alloys used in the forging process.

Superior Qualities: Damascus Steel is revered for its remarkable strength, sharpness, and resilience. It has been historically used for high-quality swords, knives, and other cutting tools.

Traditional Forging Process: The traditional forging process of Damascus steel is a closely guarded secret that has been lost to history. However, some general principles of the process are known:

Layering Alloys: Different types of steel alloys with varying carbon content were layered together to form a single billet. This might include high-carbon and low-carbon steel.

Heating and Welding: The layered billet was heated and then forge-welded together, creating a single piece of steel with multiple layers. This process helped to homogenize the alloys and remove impurities.

Repeated Forging and Folding: The billet was repeatedly heated, folded, and hammered to create more layers and distribute the alloys evenly throughout the steel. This process could be done hundreds of times, resulting in a high layer count.

Etching: After the forging and shaping process, the blade was often etched with an acid or another chemical to reveal the distinctive pattern in the steel. This pattern was a result of the contrasting layers of alloys.

While the precise techniques for creating Damascus steel were lost to time, modern metallurgists have developed methods to replicate its visual patterns and some of its qualities. Today,

Damascus steel is still sought after for its aesthetic appeal and the sense of history it carries.

The Strength of Steel

Several key factors, including tensile strength, yield strength, and hardness, determine the strength of a steel alloy. These properties are influenced by the composition of the steel and the heat treatment it undergoes:

Composition: The strength of a steel alloy depends on its chemical makeup. Steel mainly contains iron and carbon, but other elements like manganese, chromium, and nickel can be added to improve specific properties.

High-carbon steel, for example, tends to be harder but less ductile, while alloying elements can be used to modify the steel’s properties to suit various applications.

Heat Treatment: In your case, heat treatment is essential as it impacts the strength of steel. This process carefully controls heating and cooling cycles to attain the desired properties.

Two common heat treatment processes are:

Quenching: To harden steel, heat it to a specific temperature and then rapidly cool it in oil or water, a process called quenching.

This creates a hard, brittle structure with high hardness but lower toughness.

Tempering: After quenching, steel is often tempered by reheating it to a lower temperature. Tempering reduces the brittleness and increases the toughness of the steel, making it more suitable for certain applications.

Tensile Strength: Tensile strength measures a material’s ability to resist a stretching force before it breaks. It is a crucial property for structural applications.

The tensile strength of steel is influenced by its composition, heat treatment, and the presence of impurities. Steel with a higher tensile strength can withstand greater tensile forces before failure.

Yield Strength: Yield strength indicates how much stress a material can withstand before it deforms permanently, which is crucial for assessing a steel component’s load-bearing capacity.

Yield strength is influenced by both the composition and heat treatment of the steel.

Hardness: Hardness measures a material’s resistance to indentation or scratching, determined through standardized tests like Rockwell or Brinell hardness tests.

Hardness depends on the steel’s composition and heat treatment. High-carbon steel, for instance, tends to be harder than low-carbon steel.

In summary, the strength of a steel alloy is a complex interplay of its chemical composition and the specific heat treatment processes it undergoes.

These factors determine properties like tensile strength, yield strength, and hardness, making steel versatile for a wide range of applications across industries, from construction to manufacturing.

Types of Damascus Steel

Damascus steel is renowned for its distinctive patterns and excellent combination of strength and sharpness, and it can be created using various types of steel.

Damascus steel’s strength and characteristics can differ widely based on the materials used. Here are some common types of steel in Damascus steel production:

High-Carbon Steel: High-carbon steel, such as 1095 or 5160, is often used in Damascus steel. It provides hardness and excellent edge retention, making it well-suited for blades that require a sharp cutting edge.

However, high-carbon steel can also be brittle, so it’s typically combined with other materials to improve overall durability.

Low-Carbon Steel: Low-carbon steel, like 15N20 or 1018, is another common component in Damascus steel. It adds toughness and ductility to the blade, making it less brittle and more resilient.

The combination of high-carbon and low-carbon steel layers can create a balance between hardness and flexibility.

Nickel: Nickel is often used in Damascus steel to create a bright, contrasting pattern with the darker steel layers. Nickel doesn’t harden to the same extent as carbon steel but contributes to the visual appeal of Damascus steel.

Damasteel: Damasteel is a modern version of Damascus steel that uses a powder metallurgy process. It combines various high-quality stainless steels, including high-carbon and nickel alloys.

This results in a steel with exceptional strength, corrosion resistance, and the characteristic Damascus patterns.

Wootz Steel: Wootz steel, an ancient precursor to Damascus steel, is famous for its unique composition. It contains carbides and other inclusions that contribute to its distinctive patterns.

While it may not always have the same level of strength as modern steel alloys, it possesses historical significance and is highly regarded for its aesthetics.

Mokume-gane: Mokume-gane is a Japanese method that blends various metals like copper, silver, and gold to form exquisite patterns

While not traditional Damascus steel, it’s often included in the discussion due to its visually striking patterns.

It’s important to note that the specific strength of a Damascus steel blade depends on the precise combination of materials used, the layering process, and the heat treatment applied.

Bladesmiths carefully select these materials and processes to achieve the desired balance of hardness, toughness, and visual appeal.

Comparing Damascus Steel and Regular Steel

When comparing Damascus steel and regular steel, it’s important to understand that the strength of Damascus steel varies, and it can’t be generalized.

While Damascus steel is renowned for its unique qualities, there are situations where regular steel may outperform it in terms of strength. Here are some key considerations:

Damascus Steel Strength:

Strengths of Damascus Steel:

- Sharpness: Damascus steel is known for its outstanding ability to maintain an extremely sharp edge over time, which makes it a superb choice for crafting cutting tools such as knives.

- Aesthetics: The distinct visual patterns of Damascus steel add an aesthetic appeal that is highly prized.

- Toughness: Depending on the specific composition and heat treatment, Damascus steel can offer a good balance of hardness and toughness, which makes it suitable for various applications.

Regular Steel Strength:

- Consistency: Regular steel, such as stainless steel or tool steel, is engineered for consistency. Manufacturers can control its properties more precisely, ensuring reliable strength and performance.

- Specific Applications: In some specific applications, regular steel may outperform Damascus steel. For example:

- Structural Engineering: In large-scale construction and engineering projects, regular steel is preferred due to its predictable and consistent mechanical properties.

- Corrosion Resistance: Some types of regular steel, like stainless steel, offer superior corrosion resistance compared to certain Damascus steel compositions.

- High-Temperature Environments: In applications where steel is exposed to extreme temperatures, high-alloy regular steel can provide better resistance to heat and oxidation.

- Cost-Effectiveness: Regular steel is often more cost-effective and readily available, making it the practical choice for many industrial and mass-production applications.

- Customization: For highly specialized or customized applications, regular steel can be tailored to meet specific strength and performance requirements through precise alloying and heat treatment.

In summary, Damascus steel has distinctive features and looks, but it’s not universally stronger than regular steel for all uses.

Damascus steel can be stronger than regular steel in certain applications due to its layering and forging process, which enhances its properties.

Myths and Misconceptions

Addressing common myths and misconceptions about Damascus Steel’s strength is crucial to making informed decisions about its use. Here are some of the myths and the importance of accurate information:

Myth 1: Damascus Steel is Inherently Stronger Than Regular Steel:

Fact: This is a common misconception. The strength of Damascus steel depends on the specific materials used and the heat treatment process.

Some types of regular steel can be engineered to be stronger than certain Damascus steel compositions.

Myth 2: Damascus Steel is Unbreakable:

Fact: While Damascus steel can be very strong, it is not unbreakable. Like any material, it has its limits and can break or chip if subjected to excessive force or misuse.

Myth 3: All Damascus Steel is of Equal Quality:

Fact: The quality of Damascus steel can vary significantly depending on the craftsmanship and materials used. Not all Damascus steel is created equal, and the end product’s strength and performance will vary accordingly.

Misconception –1: Damascus Steel is Untempered:

Fact: Damascus steel is often tempered to balance hardness and toughness. The specific heat treatment process is a critical factor in determining the steel’s performance characteristics.

Misconception –2: The Patterns in Damascus Steel Indicate Quality:

Fact: While the visual patterns in Damascus steel are captivating, they are primarily an aesthetic feature and do not necessarily reflect the steel’s strength or quality.

FAQs

Is Damascus steel stronger than regular steel?

No, Damascus steel is not inherently stronger than regular steel. The strength of steel depends on its specific composition and heat treatment.

How is Damascus steel made, and does the process affect its strength?

Damascus steel is made through a unique layering and forging process, but its strength is determined by the type of steel used and its heat treatment.

What factors determine the strength of a steel alloy?

The strength of a steel alloy is determined by factors such as its composition, heat treatment, tensile strength, and yield strength.

Is Damascus steel stronger than high-carbon or stainless steel?

The strength of Damascus steel depends on the types of steel used. It may or may not be stronger than specific high-carbon or stainless steel.

Are there cases where regular steel outperforms Damascus steel in terms of strength?

Yes, regular steel can outperform Damascus steel in certain applications, depending on the desired characteristics.

Why is Damascus steel still considered desirable if it’s not always stronger?

Damascus Steel is valued for its unique visual appeal, craftsmanship, and historical significance, in addition to its strength.

Can Damascus steel be used for practical applications where strength is crucial?

Yes, Damascus steel can be used for various practical applications, but it’s essential to choose the right type of Damascus steel for the task.

Conclusion

In conclusion, Damascus steel is a material that captivates with its intricate patterns, craftsmanship, and historical significance.

While often admired for its unique aesthetics and balance of strength and sharpness, it is important to dispel common myths and misconceptions surrounding its strength.

Damascus steel’s strength isn’t universally higher than regular steel, and its attributes rely on the particular materials and heat treatment applied.